Business News Ultrasonics Testing onboard HQS ‘Wellington’ Historic Ship, London

페이지 정보

작성자 최고관리자 댓글 0건 조회 3,051회 작성일 19-09-17 13:44본문

The Honourable Company of Master Mariners(HCMM) invited Coltraco Ultrasonics aboard their headquarters, the historic HQS “Wellington”, alongside Victoria Embankment, London in July 2019.

HCMM are “a London Livery Company with membership open to British and Commonwealth Master Mariners from the Merchant and Royal Navies.” CEO of Coltraco Ultrasonics, Carl Stephen Patrick Hunter, is also a member.

Built in 1933, the HQS Wellington is the last surviving member of the Grimsby class of sloops, which served valiantly during the Second World War. The Wellington Trust ensure the preservation of this historic ship. The engineering team from the Trust invited members of the Coltraco team to test metal thickness and corrosion onboard using the Portagauge® 3 portable single echo ultrasonic thickness gauge - manufactured by Coltraco Ultrasonics in the UK.

Testing of the Portagauge® 3 and its sister product the Portagauge® 4 triple echo multigauge led to sound results helping to prove the ship’s worthiness for years to come.

After testing HCMM and Coltraco Ultrasonics teams discussed topics including encouraging a safety culture at sea, women in maritime and Coltraco’s CEO’s vision for eradicating modern slavery at sea. In line with the UK Government’s Maritime 2050 Strategy focussing on improving safety at sea, Coltraco Ultrasonics’ technology is designed to deliver the Safeship®: improving safety for vessel, crew and assets. The core range targets the two main causes of vessel loss sinking(by watertight integrity testing) and fire (by fire suppression system testing).

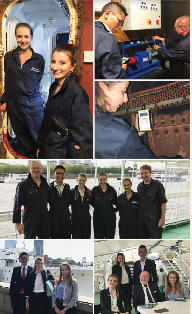

As seen in the photos, the team were able to test a range of their award-winning FLEETSAFE® package of innovative marine safety tools; suitable for crew use as they are easy to use, accurate and reliable.

1. Contentsverification of fixed gaseous fire suppression systems(CO2, NOVEC™1230 and FM-200™, etc) via Portalevel® MAX Marine

2. Convert liquidlevel to weight or mass of suppressant agent via Portasteele® CALCULATOR

3. Test watertightintegrity of watertight doors, hatch covers and MCT’s via Portascanner® WATERTIGHT

4. Inspect metalthickness and corrosion of cylinders + pipework via Portagauge® 3 and Portagauge® 4

5. Check for bearingwear and tear in rotating machinery via Portamonitor®