ETC Enhancing, improving

페이지 정보

작성자 최고관리자 댓글 0건 조회 3,375회 작성일 19-07-12 17:47본문

PlantwebTM, Emerson’s digital ecosystem, offers users everything from data to analytics to services. With Plantweb, operators can achieve measurable performance gains in production, reliability, safety and energy management. Plantweb solutions also make personnel more effective in their day-to-day jobs, empowering them with the information they need to make smarter, more strategic decisions as well as diagnose and address critical issues before they negatively impact operations.

Recently, during the Industrial Transformation Asia-Pacific(ITAP), Water & Wastewater Asia was given the opportunity to get to know Emerson’s Plantweb as well as the latest applications that set it apart, sitting down with Mr Michael Zhao, senior manager, Asia Pacific, to get to know Plantweb’s latest exciting additions.

More data

Emerson’s Industrial Internet of Things(IIoT) solution, Plantweb, is a digital ecosystem on a corporate level, incorporating numerous layers including data, security, analytics and service consultancy into one application, offering solutions to unique issues the industry faces.

“Data is the foundation of the Plantweb digital ecosystem,” Zhao said. “And for that, you need smart sensors and smart field instruments to accurately tap into it and pass on reliable data.” In the past – even as recent as half a decade ago – gathering data was a time-consuming process that included cables, scaffolding and poring over records for hours on end. It was understood that data was vital to the running of any facility, but the means of collecting data were expensive. Moreover, analytics to analyse the data was still in its infancy.

“On top of all that, mounting methods were another cause for concern. And if you wanted to access the data, you would need to cut through the layers,” Zhao added. “It takes time and effort, and everything was very difficult.”

But Emerson has had a very large hand in changing things.

“If you take a closer look at our portfolio of Pervasive SensingTM instruments, you can see that they cover pressure, temperature, flow levels, corrosion, location, and much more,” Zhao continued. “Emerson has been continuously investing in the development of wireless instrumentation every year, and we have an expanding portfolio on the market.”

Presently, Emerson is at the phase where they are launching a new application every quarter, and have found themselves at a place where they are putting out more and more integrated digital solutions as users are no longer satisfied with only a few instruments collecting simple data.

“Now, they want data analytics,” Zhao explained. “They want a true digital solution, and that is why we are investing a lot in this aspect to meet market needs.”

And using Emerson’s Plantweb may arguably be any utility’s biggest benefit. With its intuitive digital software and ecosystem, the software can monitor a great deal of things, including the overall health of pumps.

Smart

Monitoring water consumption, water balancing and flow management are just some of the terms water utility leaders are familiar with. And Emerson has the instrumentation to meet the needs of the utilities.

Wireless flow field instrumentation can help utilities keep an eye on water flow, with the RosemountTM 705 Totalising Transmitter capable of monitoring both instantaneous and accumulated flow. Systems such as Emerson’s DeltaV control system can also help ensure utilities are pumping water into the pipes at the right pressure, saving them the trouble of overpumping.

“Making sure the water pressure is right requires a closed loop system,” Zhao cautioned. “So for that, you will need to set up a feedback system. But it can absolutely be done.”

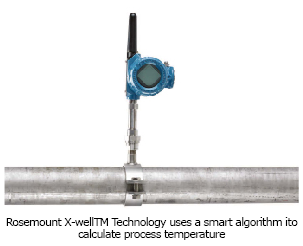

Other instruments are capable of monitoring process temperature in a non-intrusive manner, needing only to be clamped onto the pipe. Rosemount X-wellTM Technology measures the temperature of the pipe and terminal block temperature and uses a smart algorithm in the device to calculate the process temperature. Customers get a simplified solution for comprehensive process temperature measurement that removes leak points and is easy to design and install.

“We also have the corrosion sensor, the Rose mount Wireless Permasense transmitter, also a nonintrusive instrument to measure corrosion,” added Zhao.

Pipes corrode from the inside, not only making it hard to catch but hard to measure. The Rosemount Wireless Permasense system is able to provide real-time corrosion and erosion data and trends, helping facilities move maintenance fore reactive to predictive.

“People used to use coupons or other more difficult methods to measure corrosion,” he continued.

“But we’re far more straightforward here. The transmitter is based on electromagnetic ultrasonic activity, and really only needs to be attached to the outer surface of the pipe to tell you how corroded your assets are.”

The transmitter collects continuous real-time information on the thickness of the pipe, showing when the pipes will begin to corrode and degrade, and allowing users to make informed corrosion and erosion maintenance decisions. For example, Emerson’s Plantweb Insight is a suite of pre-configured, easy to integrate applications that provide real-time analysis of key asset data. The streamlined, intuitive software can help monitor a variety of important assets in a facility, including pumps.

“You can check what exact symptoms or issues the pump may have and pass the information along to the relevant parties,” said Zhao. “And this is all in an application you can install in your mobile device, so even if you leave the plant, you still have an overview of all your assets – it’s all in your hands.”

Future of work

“I’m confident that the future should be fully automated,” Zhao stated. “For example, maybe in the past, you were able to deploy two thousand sensors. But now, because they are so much more affordable and they are becoming smarter and smarter, you might deploy four thousand. On top of all that, we already have non-intrusive methods of collecting data.”

And as field instruments continue getting smarter and smarter, data will also be made more accessible and remote as well. But on top of revolutionising utilities, Plantweb is also changing workplace culture. At present, different departments can be found at different parts of the utility with varying levels of interaction. Through the use of a software platform, data from multiple applications can be combined to deliver asset-centric information to the right individual, anytime and from anywhere.

“We don’t just need to change the technology – we need to change the employees’ mindsets as well,” elaborated Zhao. “They need to keep up with this digital era. They need the strong will and want to embrace the latest technology and make changes.”

But because information will soon be coming by so easily, there will be a shift in human resources as well, with employees who had originally spent hours collecting data would find themselves at loose ends for much of their time if not properly managed.

“One of the ways to manage it is employee retraining. Manpower resources can be used for something far more sophisticated, such as providing the human interaction needed to analyse the data and making critical decisions,” Zhao suggested.

“But, in short, the workforce would need to keep up with the trends and they would also need to equip themselves with new skillsets and mindsets to embrace the digital era.”

When Emerson first introduced PlantwebTM, the digital ecosystem was considered groundbreaking. Today, with regular additions to the ecosystem, Plantweb solutions offer a scalable and secure portfolio of technologies to enable digital transformation.