Feature Story Utilizing Milbros UV Graphs improves chemical tank cleaning safety an…

페이지 정보

작성자 최고관리자 댓글 0건 조회 268회 작성일 24-11-17 14:14본문

Utilizing Milbros UV Graphs improves chemical tank cleaning safety and turnaround

- Digital solution can limit time at port and maximise cost savings

Milbros, a Veson Nautical solution, and the industry’s most reliable and extensive database of liquid bulk products, has launched Milbros UV Graphs, a product aimed at revolutionizing traditional tank cleaning practices across fleets worldwide.

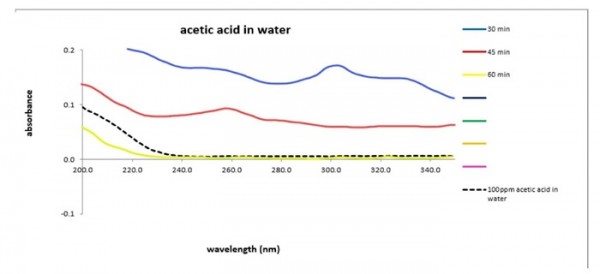

Milbros UV Graphs have been developed to work with a spectrophotometer, a machine now being installed on ships that accepts a sample of the residue, or wash water from the tank. The machine measures the absorbance of light at different wavelengths, including the ultraviolet (UV) range.

Partnered with a UV graph, the data shows how much UV light is absorbed at specific wavelengths, helping you identify any remaining tank contaminants. At present, Milbros offers at least 250 of these UV graphs with the number expected to rise.

Clients can download the required chemical chart and use the onboard spectrophotometer to create a graph. If the graph’s reading is below 100 parts per million (ppm), the tank is clean. If not, the graph will indicate how much contaminant could still be present, allowing the cleaning team to accurately calculate how much more cleaning needs to be done.

“Maritime shipping companies are facing increased pressure to limit their time at port and maximize cost savings,” Capt. Caspar Lavall, Principal Product Manager at Milbros says. “Milbros UV Graphs offers charterers, shipowners, and surveyors a safer, more efficient approach which maintains compliance while growing their bottom line.”

Source: Milbros, Veson Nautical

Capt. Lavall adds that chemical tanker cleaning is a rigorous component of safe cargo handling, and if not done correctly, can lead to environmental safety hazards, ruined cargoes, delays, and unnecessary costs.

These costs can include both recleaning of tanks that remain contaminated as well as over cleaning tanks when it is not required. UV Graphs can ensure that neither scenario affects the turnaround time of vessels whilst in port.

The use of UV Graphs complements traditional chemical tanker cleaning methods which require crews to enter confined spaces to sample various sections of the tank, exposing them to harmful chemicals. Using a UV Graph reduces the number of tank entries by allowing operators and crew to perform most of the inspections remotely.

UV Graphs are also trusted by many surveyors as a valid proof of tanker inspection and are speeding up the approval processes by allowing operations teams to submit results via email.

“The chemical tanker sector is facing new and complex challenges and having the right digital tools in place to successfully manage the risks that come with preparing vessels for volatile cargoes is vital,” Capt. Lavall concludes. “Milbros UV Graphs is a digital solution that can help establish a competitive advantage in the market.”

■ Contact: Veson Nautical www.veson.com